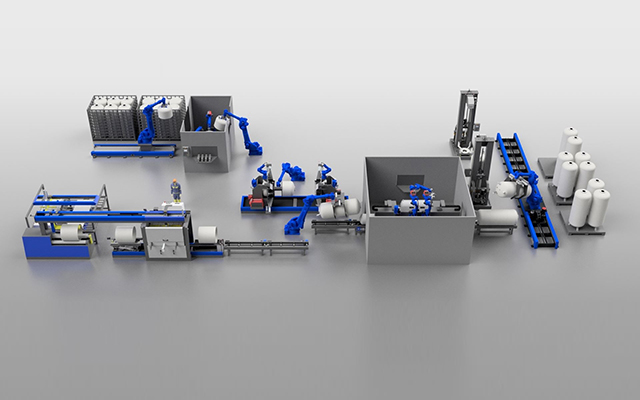

Роботизированная линия по производству бензобаков

A robot gas tank production line is a highly automated manufacturing system designed to produce gas tanks with precision, efficiency, and consistency. This advanced production line integrates robotics, computer-controlled machinery, and specialized equipment to streamline the entire manufacturing process, from raw material handling to final product inspection. The use of robotics ensures high-quality output while minimizing human error and reducing production time.The production process begins with the preparation of raw materials, typically metal sheets or composite materials, which are cut and shaped into the required dimensions using automated cutting and forming machines. Robotic arms equipped with specialized tools handle the material with precision, ensuring uniformity and accuracy in each component. These robots are programmed to perform repetitive tasks with minimal variation, which is critical for maintaining product consistency.Next, the shaped components are assembled into the gas tank structure. Robotic welding systems are employed to join the parts securely, using techniques such as spot welding or laser welding to ensure strong and leak-proof seams. The robots are equipped with sensors and vision systems to monitor the welding process in real-time, detecting any defects or inconsistencies and making adjustments as needed. This level of automation ensures that every gas tank meets stringent safety and quality standards.After assembly, the gas tanks undergo a series of finishing processes, including cleaning, coating, and painting. Automated systems handle these tasks with precision, applying protective coatings and paint layers evenly to enhance durability and corrosion resistance. Robots are also used to inspect the finished products for any surface imperfections or defects, ensuring that only high-quality gas tanks proceed to the next stage.The final step in the production line is quality control and testing. Advanced robotic systems conduct pressure tests, leak tests, and structural integrity checks to ensure that each gas tank complies with industry regulations and safety standards. Any defective units are automatically identified and removed from the production line, while approved tanks are prepared for packaging and shipment.The integration of robotics in the gas tank production line offers numerous advantages, including increased productivity, reduced labor costs, and improved product quality. Additionally, the use of automation minimizes the risk of workplace injuries by handling hazardous tasks such as welding and material handling. Overall, a robot gas tank production line represents a cutting-edge approach to manufacturing, combining advanced technology with precision engineering to deliver reliable and high-performance gas tanks for various applications.

продукт

классификация:

Линия по производству роботов для бензобаков

-

Линия по производству роботов для бензобаков

Их классификация: Линия по производству роботов для бензобаковмнения: 78номер:Время выпуска: 2025-09-08 11:21:33АЛиния по производству роботов для бензобаковпредставляет собой узкоспециализированную автоматизированную производственную систему, предназначенную для производства широкого спектра сосудов под давлением, включая баллоны для сжиженного нефтяного газа, баллоны с пропаном, контейнеры для природного газа, промышленные резервуары для хранения и бытовые газовые баллоны. Эти резервуары широко используются в жилых домах для приготовления пищи, отопления, промышленного снабжения топливом, химической обработки и хранения энергии.Традиционные методы производства бензобаков в значительной степени полагал...

новости

классификация:

Нет результатов поиска!

случай

классификация:

видео

классификация:

Нет результатов поиска!

скачать

классификация:

Нет результатов поиска!

вербовка

классификация:

Нет результатов поиска!

Рекомендуемые продукты

Нет результатов поиска!

WhatsApp

WhatsApp телефон

телефон